Written by Lake Engineering Solutions Corrosion Engineer, Dean Kenny

A good supplier of corrosion protection consumables should always evaluate which products or combination of products is the most suited for the intended application. When it comes to corrosion protection, the application of products is just as important as the products selected, and full standard operating procedures must be adhered to in order to give standardisation to the task at hand. In this article we delve into a few of the variables that influence corrosion protection.

Corrosion inhibitor liquids, also known as “Rust Preventatives” (RPs), are available in a wide range of options and formulations. They primarily protect by creating a continuous temporary barrier on the surface of the metal that prevents corrosion.

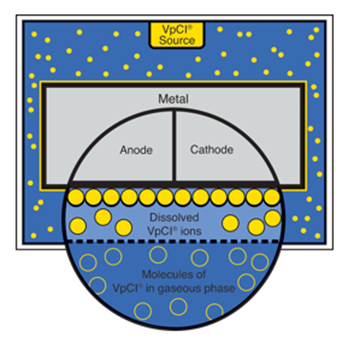

Typically, RPs are mineral oil or solvent based, however more environmentally aqueous-based or sustainable oil-based products are also on the market today. Volatile Corrosion Inhibitor (VCI) or VpCI® (Vapour Phase Corrosion Inhibitor) packaging products are offered in many options to protect products in various applications, including outdoor use and long-term storage. VCI/ VpCI® packaging is available in polyethylene bags, wraps, film as well as in kraft paper and emitters.

These work by diffusing protective molecules into a sealed enclosure, which are then attracted to the metal’s surface by adsorption. VCIs/ VpCI’s® form a thin, invisible layer that passivates the metal surface and protects it from corrosion. RPs and VCI/ VpCI® packaging can be used together for a comprehensive protection system.